Types of potato diggers for a mini-tractor, principle of operation and selection criteria

Attachments for a mini-tractor are indispensable equipment in the household. One of the most popular devices is the potato digger. There are many varieties and models on the market. But if you make such a design yourself, financial costs are significantly reduced.

The content of the article

What is a mini tractor potato digger

A modern potato digger is a passive attachment for connection to equipment with a power take-off shaft. It works like a shovel or plow, but teeth or rods are welded to the parts.

The main plow goes deep into the ground, loosens and turns it over. The potato clings to the rods, rises and remains on the surface.

What does it look like

Outwardly, the technique resembles an ordinary wheelbarrow on wheels, but differs in the presence of teeth and mechanisms for rotating the conveyor belt. There is an element for fixing to a mini-tractor.

Principle of operation

The mini tractor potato digger helps you extract potatoes, beets, carrots and other root vegetables from the ground.

It happens as follows:

- the share plunges into the ground to a depth of 20 to 50 cm;

- when the mini-tractor moves, it pulls out the root crop along with the soil;

- the mixture is sent to the grate;

- the soil is gradually poured back into the ground, and the peeled tubers fall to the surface.

After that, it is enough to walk across the field and harvest. If we compare it with digging up a vegetable with a shovel, then a potato digger significantly increases labor productivity and reduces the consumption of physical strength.

Reference. Any model allows you to harvest accurately. The tubers are practically not damaged. If the surface of the vegetable is slightly scratched, it is better to eat it right away.

Varieties

All potato diggers are divided into 2 large groups: single-row and double-row. The former are distinguished by the presence of one row of teeth, the latter are equipped with two rows of rods and are considered more complex devices.

Single row are:

- Vibrating, or roaring. The most common option. The models are equipped with a horizontal share, which digs the ground during operation. It looks like an inverted P. It dives to a depth of 20 to 30 cm. There are rods at the back. The distance between them prevents the tubers from falling back into the newly dug trench. A vertical piston is attached to the rods to create vibration. The lumps are broken up under the vibratory flow and sent back to the field. Tubers fall on the surface.

- Conveyor. The principle of operation is the same as that of vibration technology, but there are differences. The horizontal ploughshare replaces flat, forward-facing tines. A special drive starts the conveyor belt. On it, the potato is detached from the ground and then falls to the ground.

- Fan-shaped. A simple design, including a shovel bayonet share and a fan of metal rods. Tubers from the soil move backwards along the plowshare, and then fall through the rods to the ground surface. Such a potato digger is perfect for working together with a mini-tractor and walk-behind tractor.

- Drum. The technique is distinguished by the presence of a rotating drum. Potatoes get into it, which, after clearing from the ground, moves down.

- Equestrian. The principle of operation differs markedly from previous models.The ploughshare lifts the tubers and transports them to a rotating wheel. This element moves in the opposite direction, pushing the crop towards the side bundles of metal rods. Then the tubers fall to the ground, but a little further than the dug trenches.

In households and on small farms, it is the single-row potato diggers that are used. In fields with an impressive volume of vegetables, double-row models are used. We will not describe them in detail, since they are intended for connection to heavy machinery.

Review of the best models

Russian-made potato diggers are endowed with excellent technical characteristics and show good performance. Let's consider the most popular models.

"Scout"

It is a conveyor potato digger for high quality pre-processing of vegetables.

Features:

- compatibility with mini-tractors "Scout", equipping with a three-point suspension system and a power take-off shaft;

- connection to models T-12, 15, 18, 24 and 25 is permissible, but using a drive belt of the corresponding class;

- adjustable knife depth up to 28 cm;

- power indicators - from 12 to 25 liters. from.;

- power take-off shaft speed - 540 rpm;

- drive belt type - B2360, B25550 or B2600;

- travel speed - from 2 to 7 km / h.

The cost of attachments starts from 20,000 rubles.

KKM-3

This crumbling potato digger for connection to MTZ-132N is designed for digging and laying vegetables on the soil surface.

The model provides for adjustment of the immersion depth of the teeth.

Features:

- productivity - 0.05-0.2 ha / h;

- speed - 1.1-2.1 km / h;

- soil capture depth - 20 cm;

- required drive - PC-3;

- cost - from 12,500 rubles.

The technique has shown itself well in working with wet and hard soils. At the same time, it is able to loosen the soil littered with stones up to 8-9 t / ha.

4UD-1

Roaring potato digger for extracting vegetables from the soil and partially separating them from the ground, followed by laying them on the surface of the field.

Features:

- suitable for work in tandem with mini-tractors and tractors of the class from 0.6 tf with a capacity of more than 20 hp. from.;

- installation takes place on the rear three-point hitch using the PTO drive;

- pickup depth - from 15 cm;

- speed - up to 6 km / h;

- productivity - up to 0.225 ha / h;

- type of construction - single row.

The cost of the model starts from 1,800 rubles.

Bomet Z-655

The vibrating potato digger with rear discharge has a compact size (1.7x1.5x1.15 m), therefore it is used on small flat or hilly land plots with medium compacted and light soil.

Features:

- compatibility with any mini-tractor models with a capacity of more than 15 liters. from.;

- power take-off shaft speed - 540 rpm;

- soil capture depth - up to 20 cm;

- working speed - 5 km / h.

Side discharge allows the crop to be placed 50 cm from the main trench. This ensures that all tubers rise without any damage. The cost of the model is from 65,000 rubles.

Wirax

Single-row conveyor potato digger for any mini-tractors of traction class 0.9 with a capacity of 20-35 hp. from. Cultivates only loose soils without stones.

Features:

- soil capture depth - up to 25 cm;

- working speed - 8 km / h;

- the ability to work on surfaces with a slope of up to 6 °;

- completed with two rubber-fabric conveyor belts of Italian production;

- cost - from 60,000 rubles.

KK-1

The single-row type transporter potato digger is suitable for connection to heavy walk-behind tractors and mini-tractors with a capacity of 18 hp. from.

Features:

- capture width - 65 cm;

- digging depth - up to 25 cm;

- working speed - 4 km / h;

- connects to the equipment "Salute", "Ugra", "Neva";

- cost - from 55,000 rubles.

Criterias of choice

Before buying, it is important to decide on the following parameters:

- Power. The higher it is, the more productive the technique is.

- Width and depth of capture. Here, attention is paid to the depth of the tubers and the width between the rows.

- Speed. Affects the speed digging... It is good if the car moves at a speed of 6 km / h.

- What type of soil is the digger intended for? Information is indicated in the technical specifications of the model. If you pick up the wrong sample, the technique will quickly fail.

How to make a potato digger with your own hands

If you do not want to spend money on buying attachments, you should try to assemble it yourself from scrap materials. The following is an instruction for making a simple potato digger.

Required materials and tools

To create a homemade potato digger you will need:

- frame;

- lattice;

- pipe with a diameter of 20 cm for making a share;

- ready-made chain mechanism for fastening;

- steel or rubber wheels;

- welding;

- Bulgarian;

- sharpener;

- bolts.

Drawings, schemes

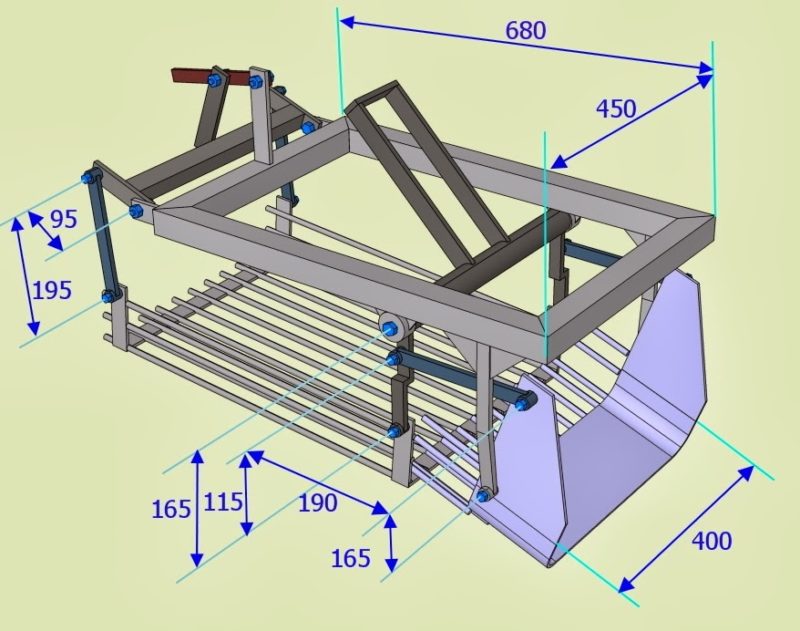

There are a large number of schemes for the manufacture of attachments, but it is better to choose a scheme for assembling a vibrating potato digger. This simple design does not require a high level of skill. Only minimal knowledge of welding is required.

Step-by-step instruction

The following diagram will allow you to assemble a reliable potato digger from simple materials:

- For the frame, you need a corner with a section of 60x40 mm. Gussets-reinforcements of the corners of the frame and other units are cut out of a steel sheet with a thickness of 6-8 mm. All parts are fixed by welding or bolts. It is good if fastening methods are combined.

- A lattice is cooked from rods and steel strips with a diameter of about 10 mm. The finished structure is connected to the shaft, and the fixation points are bolted.

- A pipe with a diameter of 20 mm is cut with a grinder, a ring is made from it. The resulting product is processed with a sharpener. The sharp share is fixed to the frame and the elevator with bolts. The diameter of the fasteners is 10 mm.

- Install the hubs on the sides of the hinge.

- The ready-made trailing mechanism is fixed.

- Wide wheels are mounted. Better than 2 pairs.

The assembly of equipment is carried out only on a flat surface. A serviceable tool is used, without burrs and chippings.

Operating rules

Using a potato digger implies taking into account the following tips:

- do not stay in front of a working mini-tractor with attachments;

- it is forbidden to jump into the vehicle on the move;

- after the end of work, the drive belt must be removed from the engine;

- it is not recommended to lubricate the working units of the switched on equipment;

- it is better to work with guards and guards.

It is interesting:

Advantages and disadvantages of growing potatoes using Dutch technology

How to make a shovel for digging potatoes with your own hands

Conclusion

Making a potato digger at home is not difficult if you choose the most suitable scheme and drawings. The main thing is to follow the instructions and securely weld the parts. In the process, be sure to use personal protective equipment.